Preventing Global Warming

Energy-saving emphasis in products

The Hoshizaki Group actively works to develop and expand its lineup of environmentally conscious products.

As an example of our efforts, Hoshizaki America has worked to expand its lineup of ice machines with high energy-saving performance and environmentally friendly commercial refrigerators that reduce greenhouse gas emissions.

In recognition of these efforts and others, Hoshizaki America has received the ENERGY STAR Partner of the Year—Product Brand Award for 12 consecutive years as well as the Partner of the Year—Sustained Excellence Award, the highest award given to winning companies, for 9 consecutive years.

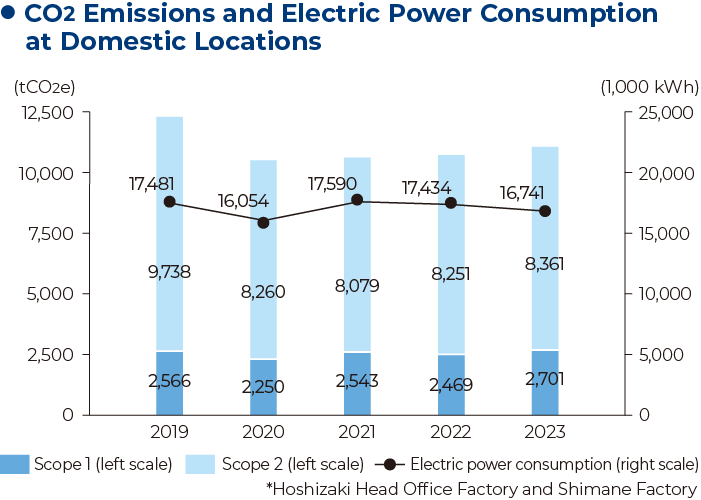

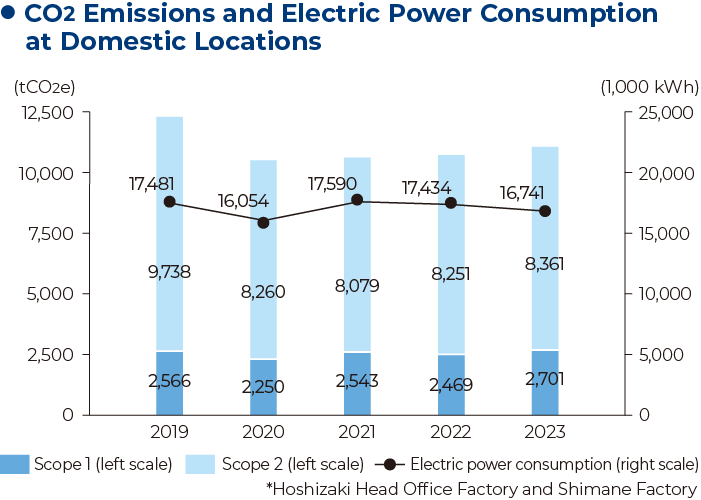

Reducing CO2 emissions in Japanese production processes

The Hoshizaki Group recognizes that reducing greenhouse gas emissions is an issue for the company to tackle. As we comply with environmental regulations in various countries, we are also introducing energy-saving facilities, improving facility operations, and increasing operational efficiency in order to reduce CO2 emissions from energy sources generated in the course of our business.

In 2023, Hoshizaki’s CO2 emissions (Scope 1 & 2) totaled 11,062 t CO2e, an increase of 3.2% from the previous year.

By operating demand monitoring equipment and upgrading to high-efficiency equipment, our electricity consumption decreased 4.0% from the previous fiscal year to 16,741 thousand kWh. However, we were affected by the increase in the CO2 emission coefficient of retail electric utilities.

We will continue to implement priority measures to reduce CO2 emissions in order to achieve our 2030 CO2 emissions reduction targets.

* For priority measures, please refer here.

Reducing CO2 emissions overseas

Western Refrigeration Pvt. Ltd., a member of the Hoshizaki Group in India, installed a photovoltaic system spanning 5,000 m2 on the roof of the Sanjan Plant at the time of the plant’s construction in 2017.

A photovoltaic system was added in 2022.

In 2023, a photovoltaic system was installed on the rooftop of the Tadgan Plant. These facilities generate a total of 2,200 kWp of electricity, with an estimated CO2 emissions reduction effect equivalent to planting about 88,000 trees.

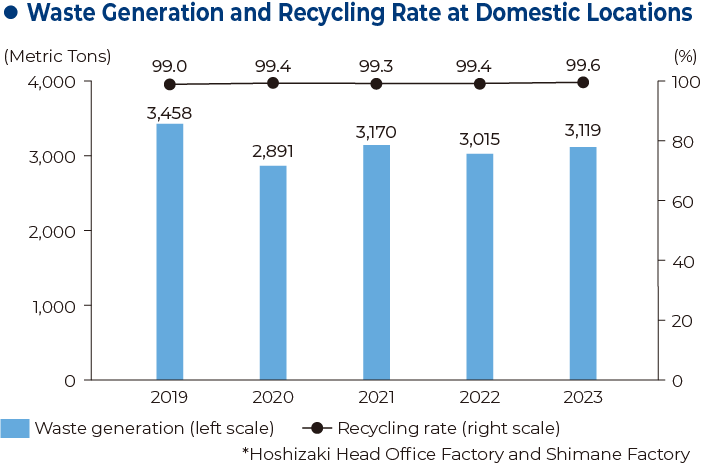

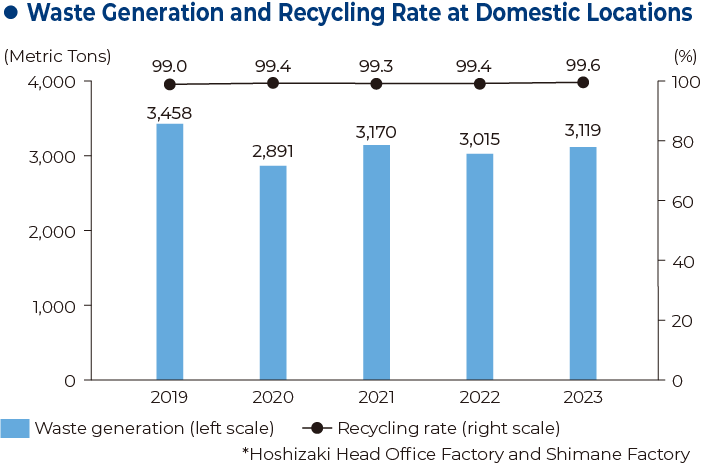

Reducing the Waste Generation

The amount of waste generated at Japanese sites increased 3.4% from the previous year to 3,119 tons.

Although the amount of waste increased from the previous year due to the increase of the production volume, the reuse (recycling) rate of waste and other materials reached 99.6%; this was achieved by promoting the sorting and reuse of waste and other materials.

We will continue to reduce the generation of waste and other materials and make efforts to further improve our recycling rates.

Reducing supply chain waste generation

As an initiative to reduce the amount of waste generated across the supply chain, we have transitioned away from wood frames in the packaging of most products, in favor of simplified packaging made from cardboard.

Packaging is designed to minimize waste by not covering the entire product, instead covering only the upper and lower parts that are easily damaged.

As a result, not only is product loading weight reduced but packaging is also easier to dispose of when products are unpacked at the receiving sales company.

In addition, suppliers ship components to our manufacturing sites in returnable containers, thereby limiting points of cardboard use.

Protecting Water Resources, and Measures to Address Soil and Groundwater Contamination

Reducing water consumption in production processes

The production processes within our Japanese group do not use large amounts of water; rather, the use of water is limited to such purposes as indirect cooling.

In addition, all factories are located in areas with low water-related risks, such as drought, and tap water, water for industrial use, and groundwater are used appropriately in accordance with the circumstances that prevail in each area.

Wastewater is appropriately disposed of and discharged into sewer drainage systems or public water zone drainage systems.

Environmental considerations for dishwashers

The JWE series of commercial dishwashers features technology that reduces the volume of water needed to rinse dishes while maintaining cleaning performance.

At the rinsing stage, the machine draws in clean water, with dirty water from the washing cycle draining out as overflow. This reduces the amount of water used per load and facilitates rinsing with just a small amount of water.

In addition, less water means less detergent and less energy consumed to heat the water, thus realizing more environmentally conscious products.

Environmental considerations for electrolyzed water generators

Electrolyzed water generators use positive and negative electrodes to electrically separate saline solution into acidic electrolyzed water (hypochlorous acid water) and alkaline electrolyzed water.

Compared with sodium hypochlorite, acidic electrolyzed water has a high sterilization capability even at low chlorine concentrations yet has low persistence and leaves almost no chlorine odor. It is therefore used to wash foods, disinfect cooking utensils, and clean and sterilize equipment and common spaces in nurseries, daycare facilities, seniors’ care facilities, and so on.

In addition, the solution can be prepared at specified concentrations without the need for dilution, making cleaning less time-consuming and reducing the amount of water needed.

The alkaline electrolyzed water has cleansing properties, with the power to break down proteins and emulsify fats. It can be used to clean cooking utensils with less environmental impact than regular cleaning agents.